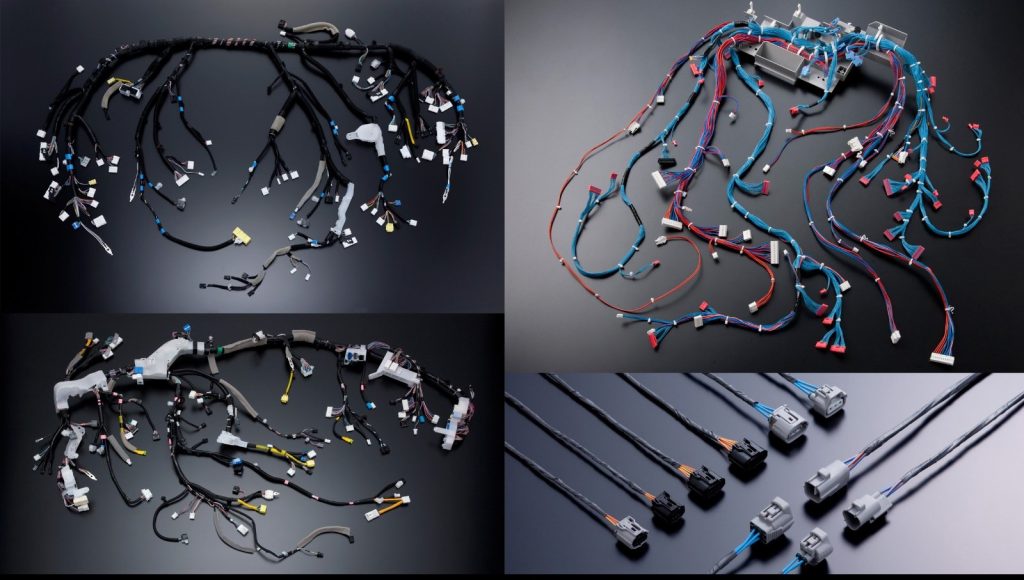

Crafting a personalized wire assembly is a pivotal undertaking that demands meticulous attention to the minutest details. The pivotal role of a wire assembly cannot be overstressed, given that a defective wire or suboptimal connection may result in substantial delays and financial setbacks. To ensure the production of a high-quality wire assembly that aligns with the specific needs of your application, it is imperative to adhere to a systematic approach.

The initial phase of wire assembly design involves meticulous planning. This encompasses the identification of materials to be employed, determination of necessary dimensions, and adherence to other quality specifications. The choice of materials for wires and casing is contingent upon the unique requirements of the application. Additionally, specifying the length of wire between each connection, accounting for any required slack, is crucial.

Following the finalization of the design, the creation of a prototype becomes imperative for early fault detection and rectification, minimizing potential issues during the later stages of production. Engineers leverage the prototype not only to identify and address flaws but also to explore opportunities for more efficient layouts and refinements.

With the approved design, preparations for assembly commence. This involves cutting wires to the prescribed lengths, stripping casings to reveal cores, and readying connectors. Automated tools, such as wire cutting machines and semi-automated crimpers, are employed to expedite the process while maintaining quality and consistency.

The ultimate step involves assembling the wires and connectors into a harness, necessitating a meticulous manual process to ensure dimensional adherence to the design specifications. The incorporation of high-quality tools, including injection mold machines, automated cutters and strippers, and insertion-extraction tools, enhances the efficiency and efficacy of the process.

When selecting a wire assembly manufacturer, it is crucial to opt for one equipped with the requisite tools, design capabilities, and manufacturing prowess. Miracle Electronics stands out as a premier wire assembly manufacturer in India, offering an extensive range of both standard and customized wire assemblies. Their ISO 9001 and AS9100C certifications underscore their commitment to meeting international quality standards in their production processes.

For top-tier transformers, inductors, magnetics and wire harnesses, reach out! Call: 619-806-1558 Visit: www.intmassy.com #WireAssembly #WireAssemblyManufacturing #WireAssemblyManufacturer #CustomizedWireAssemblyManufacturing

Recent Comments